Master Of Science (MoS) speciality Advanced Manufacturing and Materials Science (AM²S)

Campus

Campus Arts et Métiers d’Aix-en-Provence

Program

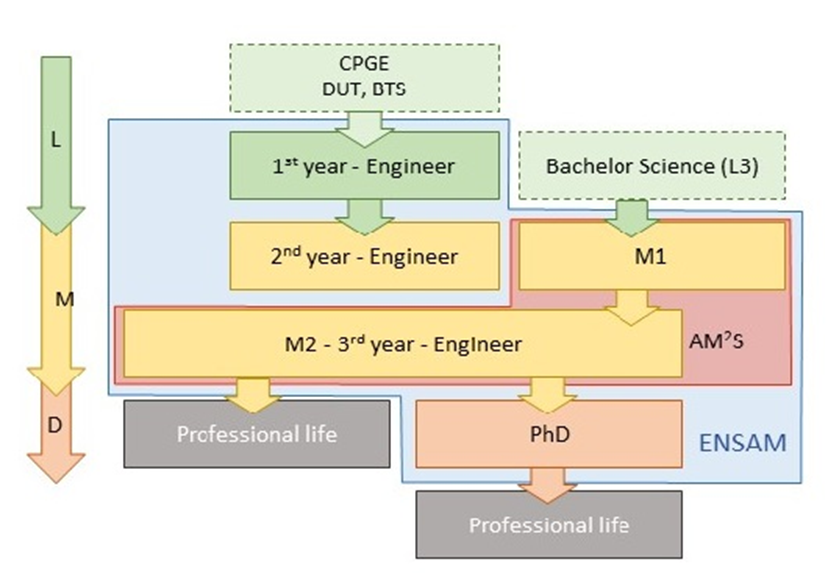

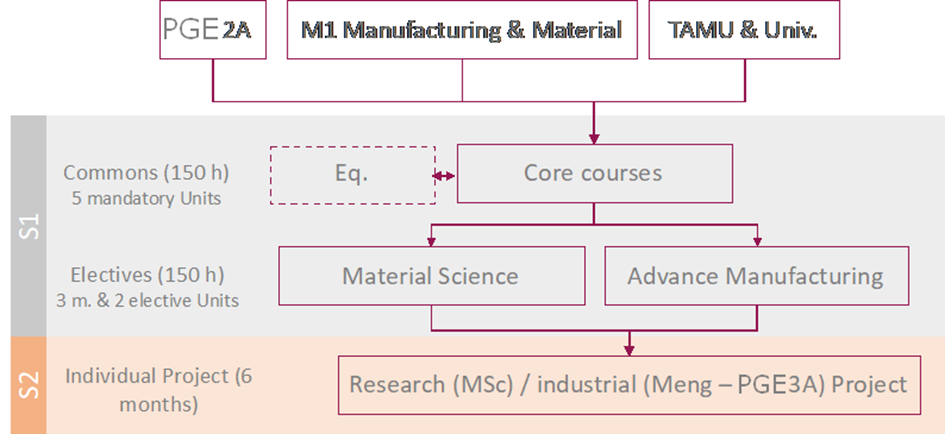

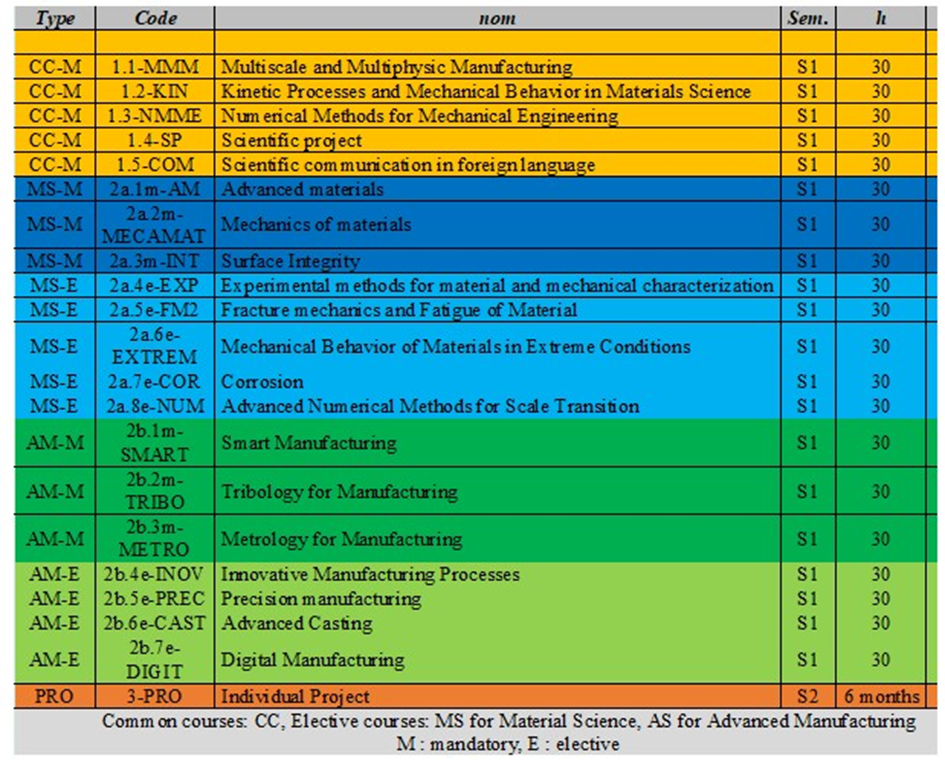

Figures 1 and 2 provide the flow chart and program structure of the AM²S program. The courses are composed of:

- Core courses (150 hrs., 15 ECTS) with 5 mandatory teaching units (TUs) during the first semester. These units will allow students to understand the relationship between materials and processes with i) the new context of smart and digital concepts (3 TUs), ii) the place of the engineer or researcher in the world (2 TUs). These TUs will allow students to develop their scientific communication, team project organization and language skills.

- Two Elective paths (150 hrs., 15 ECTS) with 3 mandatory TUs and 2 elective TUs during the first semester:

- "Materials Science elective": with this path, students will improve their knowledge and acquire the skills to understand the effects of processes on materials use in relation to the surface/volume functionalization of mechanical parts. The 2 elective TUs will be chosen from the 5 TUs offered.

- "Advanced Manufacturing elective": these elective courses will allow students to improve their understanding of smart manufacturing by addressing the concept of digital processes based on the expertise of the MSMP laboratory. The 2 elective TUs will be chosen from the 4 TUs offered.

- Individual project (30 ECTS) for 6 months during the second semester. The internship will be done in a research structure (university laboratory, research department in a company in the field).

The courses combine lectures, seminars, specific training on characterization devices (SEM, XRD, etc.), processing machines (foundry, etc.) and computers for numerical simulation or/and smart computing. For some TUs, a small individual or group research project is used to improve students’ soft skills.

The list of TUs is given in Table 1 and the detailed syllabus can be load here.

Figure 1 : Flow chart of AM²S

Figure 2 : Program structure of AM²S

Table 1: List of teaching units

Objectives

With the evolution of manufacturing processes from the skills required to the industry of the future 4.0, engineering education must adapt to new future challenges. This program will provide future engineers or researchers the basic knowledge and skills to understand, use and develop Industry 4.0 concepts based on smart approaches including the digital revolution.

The Master’s specialization “Advanced Manufacturing and Materials Science” (AM²S) is positioned at the crossroads of France, Europe, the Mediterranean Basin and the U.S. industrial ecosystem, by offering the AM²S courses in English for the Master of Science degree (MSc) and PGE 3rd ENSAM / Master of Engineering (MEng).

The objectives are also to increase students’ knowledge in the field of manufacturing processes and the materials science through multi-physics and multi-scale approaches, including smart and digital concepts. In other words, this program will focus on innovative scientific fields, from the physics and chemistry of materials to the use of manufactured parts, by developing the duality between experimentation and numerical simulation.

Strengths of the training

The scientific objectives of the AM²S program emphasizes a high-level scientific approach by:

- Improving the knowledges of the relationships between the Material Science and the Manufacturing Processes,

- Using multiphysic and multiscale approaches to better understand the relationships between materials/mechanics/processes,

- Mastering the numerical tools for optimizing the design of structures and parts high added value,

- Using new technologies, in particular smart digitalization, big data, and numerical simulations.

These objectives will allow students to move on to a PhD program with knowledge and skills in the materials sciences and/or smart manufacturing.

The scientific objectives will be completed by several professional skills and vision by :

- Understanding the current and future challenges for the manufacturing industries,

- Knowing the technologies related to advanced and smart manufacturing,

- Developing a transversal approach coupling materials, mechanics, and manufacturing in the context of the future industry 4.0,

- Acquiring skills for the choices and uses of materials and manufacturing processes in the field of transport or energy,

- Giving a MSc or MEng level to the students.

Acquired skills

Students will acquire theoretical and experimental knowledge in materials science and advanced manufacturing, and will learn laboratory techniques and scientific instrumentation in these fields to prepare for a future career in an industrial environment or research laboratory.

The program focuses on the relationship between the materials (proprieties) and the manufacturing processes for specific functionalization of mechanical parts. Through the Materials Science (MS) elective, the program will provide additional insights on the effects of manufacturing processes on materials' microstructure modifications and their consequences on part uses. With the Advanced Manufacturing (AM) elective, the program will provide additional insight on advanced and smart manufacturing processes with hard materials knowledge to understand the multiphysical phenomena involved during material transformation.

More specifically, the scientific skills acquired cover the following areas:

- Ability to select the elementary physical-chemical phenomena involved during manufacturing processes,

- Ability to understand the relationship between these phenomena,

- Ability to select the representative scales for these phenomena in relation to the objectives of the process uses,

- Ability to introduce the functionalization of mechanical parts,

- Ability to optimize the simulation of the processes in relation to the functionalized surfaces,

- Ability to use smart approaches for solve inverse problems from the functionalization to the technological parameters of processes.

The optimization of the relationship between materials/manufacturing processes requires mastering many experimental and simulation methods. This program trains highly skilled scientists and engineers to understand and use the associated technologies:

- Ability to understand multiphysical and multiscale analysis for surface and material characterization,

- Ability to choose the best experimental methods to characterize microstructure modification due to the manufacturing processes,

- Ability to instrument manufacturing processes in order to understand and optimize them,

- Ability to use numerical simulation of multiscale and multiphysical processes in relation with experiments,

- Ability to use smart methods to improve the efficiency of numerical models and online processes supervision.

Main scientific and educational coordinators of the MSc

L. Barrallier : Program Director for the MSc & MS Elective, 1.4-SP TU Responsible

M. Bedel : 2b.6e-CAST TU Responsible

F. Chegdani : 2b.2m-TRIBO TU Responsible

D. Depriester : 2a.8e-NUM TU Responsible

M. El Mansori AM Elective Responsible, 2b.1m-SMART, 2b.3m-METRO, 2b.5e-PREC TU Responsible

R. Knoblauch : 2b.1m-SMART

A. Fabre : 2a.3m-INT TU Responsible

M. El Hadrouz : 2b.5e-DIGIT TU Responsible

L. Héraud : 3-PRO TU Responsible

S. Jégou : 1.2-KIN & 2a.4e-EXP TU Responsible

R. Kubler : 2a.2m-MECAMAT & 2a.5e-FM2 TU Responsible

H. Ramezani-Dana : 2b.4e-INOV TU Responsible

Associated technological platforms

The formation is backed by the 2 MSMP Lab. Plateforms :

Manufacturing processes: Modern and efficient experimental means, allowing the implementation of instrumented processes at scale 1, the conduct of experimental physical analyses, the formalisation and modelling of physical and mechanical phenomena arising during the implementation of manufacturing processes (machining, additive manufacturing, foundry...).

Characterizations and Treatments of materials : Optimisation of microstructures in order to improve mechanical properties. Microstructure characterization tools and corresponding methods developed (X-ray diffraction, observations and physicochemical analyses, thermal, thermo-chemical and mechanical treatments, multi-scale mechanics and surfaces)

Knowledge assessment

The knowledge and skills acquired are evaluated through traditional examinations and continuous assessment. Grades earned through continuous assessment are not subject to a second session. The specific rules for evaluation are approved each year by the steering committee. An exam session is organized at the end of the first semester. A catch-up session is held 15 days after the last examination in the initial exam session.

Each teaching unit is graded from 0 to 20, and the procedures for validating the TUs are those in force in the ENSAM Teaching Rules. The evaluation procedures are specified by each TU coordinator. For lecture courses, the test may include one or two written exams, at the discretion of the TU coordinator. Training, projects, and courses are evaluated both on the basis of continuous assessment and a final project (report and/or oral presentation).

Teaching methods

Traditional teaching methods (lectures/courses, training, projects) are used in this program. However, new approaches, such as flipped classrooms, active projects, etc. are used as complementary teaching methods in some TUs.

Opportunities

This program aims to train future PhD students and research engineers with high qualifications in their specialities. The working methods and the skills acquired will allow students to have a career in: i) major manufacturing companies in several sectors, such transport or energy; ii) research laboratories in mechanical or/and materials engineering. Hard knowledge on technical skills will complete their training.

Another objective is to train future engineers with expertise in materials sciences and advanced manufacturing. The goal is to prepare students for a career in industry with a scientific approach in the fields of the matter transformation or/and part manufacturing. These approaches will complete the technical expertise acquired during the industrial/research project.

ADMISSION

Admissions criteria

- Foreign and French students may apply to the program

- M1 graduates only (or ENSAM PGE 2nd year students) in mechanical engineering, materials sciences or manufacturing

- English level: the minimum requirement is TOEFL iBT 81/120 (or equivalent) or IELTS 6.0

- Admission is based on academic excellence, motivation of the candidate, and coherence of their professional project.

Application deadline

- ENSAM PG2 student : 2B choice (internal procedure), professional experience is not guaranteed except research internship in a company

- Other students : see application from here (opening in February)

Partners

Scientific support :

- MSMP : Mechanical Surfaces and Materials Processing Lab., EA7350, Aix-en-Provence, Châlons-en-Champagne, Lille

- TESS-TAMU (Texas A&M University) Center for Intelligent Multifunctional Materials and Structures – CiMMS, Institute for Manufacturing Systems – IMS, College Station, Texas, USA

Universities : University of Bristol, Danish Technical University, Karlsruhe Institute of Technology, Texas A&M University.

Industrials : Airbus, Renault, PSA, CEA, Safran, Thyssen Group, LISI Automotive, Essilor, Saint-Gobain, Sateco, STIL Compagny

Institutionals : Cluster Safe, Henri-Fabre Project, IRT M2P.

Target companies

Companies in the automotive, rail, aeronautics, space, steel, energy sectors.

Examples of internships/projects

- Stress relaxation in welded joints, application for automotive – PSA

- Nitriding of tool steel, effect of alloying elements – LISI automotive

- Effect of nitriding during electric steel plate fabrication – Thyssen Group

- Data-driven tribo-peening process qualification – Saint Gobain

- Smart functionalization of casting materials for storage and transportation of hydrogen, Saint-Gobain

- Design innovative molding solutions to achieve tire performance, Michelin

- Application of Directed Energy Deposition for the repair of surfaces and tribological behaviour, Texas A&M University

Practical information

- Teaching language: English

- Number of hours: 300 hrs. of academic classes

- ECTS credits earned: 60

- Annual cost: tuition fee for EU/EEA and non-EU/EEA citizens: around €243/academic year. Must be paid by registration day at the latest.

- Social security costs may be added (maximum €217)

- Program location: Aix-en-Provence

To apply online : admissions

Contact

Please send the necessary documents to Dr. Sébastien Jégou to the following address :

Campus Arts et Métiers, 2 cours des Arts et Métiers F-13167 Aix-en-Provence, France

Key-words

Materials Science, Manufacturing, Numerical methods, Big data, Mechanics, Modelling, Residual stress modelling, Kinetics, Phase transformations, Mechanical Behaviour, Experimental investigations, Mechanics of materials, Digital manufacturing, IT, Computer simulation, Industry 4.0, Innovative manufacturing, Digital Twinning, Manufacturing Creativity, Manufacturing tribology, Friction, Machining, Casting processes and simulation, materials properties, materials design.