A YEAR IN SINGAPORE WITH THE DESCARTES PROGRAMME

Amine Ammar, a lecturer in Angers, has been in Singapore since 1 September as part of the DesCartes scheme.

Amine Ammar, a lecturer in Angers, has been in Singapore since 1 September as part of the DesCartes scheme.

Arts et Métiers and ESI Group join forces for an international teaching and research chair in the field of engineering and digital engineering of materials, processes, structures, and systems.

CREATE ID is an international teaching and research chair between Arts et Métiers and ESI Group, a leading provider of virtual prototyping software and services specializing in the physics of materials. It focuses on several research areas related to the industry of the future:

This research can be applied in several sectors: automotive, aeronautics, naval, metallurgy, health...The Chair will also aim to develop engineering training, and education in these research areas.

All the informations of PLM CHAIR

This chair focuses on two main objectives:

Launched with the company Cagemini, this Chair marks the coming together of the industrial world, and the academic and scientific world.

Capgemini, Carnot Arts Institute

Developing and enhancing research activities in recycling and eco-design: Such are the ambitions of the Urban Mines Chair, created in 2014 by the eco-organization Ecosystem, in partnership with the ParisTech Foundation and three grandes écoles: Arts et Métiers, Chimie ParisTech and Mines ParisTech.

This teaching and research chair is dedicated to waste electrical and electronic equipment (WEEE), which contain many recyclable materials, including rare metals. In other words, WEEE are absolute "urban mines" that are widespread today. In the context of depleting natural resources, the exploitation of WEEE can be part of a circular economy approach, in accordance with the principles of sustainable development. The chair was renewed for 5 years (2019-2024) in March 2019, it is version 2.

The Chair's missions are threefold: the development of new quality secondary materials, the definition of economic models for recycling, and training actions. In terms of research, three main areas of focus are identified:

This theme brings together specialists in the physical chemistry of processes, materials chemists, physical chemists of colloids and specialists in analytical sciences, pooling their skills to study the interface of materials and processes.

Two Arts et Métiers laboratories are working on this topic: the I2M-IMC (Institut de Mécanique et d'Ingénierie - Mécanique et Conception) branch of the Chambéry Institute, the school's center of expertise on recycling and eco-design, and the PIMM (Procédés et Ingénierie en Mécanique et Matériaux) laboratory, which brings together specialists from various fields: mechanics of materials and structures, polymer chemistry, aging and recycling, etc.

The CGS (Centre de Gestion Scientifique) team at Mines ParisTech is interested in the economic, managerial and governance dimensions of urban mines. It has recognized expertise in the fields of innovation management, CSR (corporate social responsibility) and eco-design.

Contractual research is an essential component of the relationship with the socioeconomic world. The school has a subsidiary dedicated to this activity, AMVALOR, which is developing an ambitious program of chairs.

Arts et Métiers holds four research chairs on subjects with a strong societal and/or industrial impact, such as :

- The environment : The WEEE chair, devoted to the eco-design and recycling of electrical and electronic equipment waste with ESR, and the Product Lifecycle Management (PLM) of the Future chair, developing innovation in the field of product lifecycle management methods and tools as well as training employees in PLM tools and preparing them for Industry 4.0 in partnership with Capgemini.

- Clean mobility : The non-linear dynamic chair for the absorbers of the future with Valeo, which aims to reduce vibrations linked to the use of cleaner technologies;

- Intelligent industrial systems : The Create ID Chair with ESI, on advanced numerical methods for personalized real-time simulation (Hybrid Twin) of the behavior of materials and manufacturing processes.

- Health : The BiomécAM chair with Proteor (a French specialist in orthopedic devices), the Société Générale's disability mission, Covéa (a mutual insurance group), and the Yves Cotrel foundation for research in spinal pathology;

- Intelligent industrial systems : a production systems chair designed to introduce the technological building blocks of the Factory of the Future into the production systems of very small businesses and SMEs with the Union des industries et métiers de la métallurgie, ThyssenKrupp and the ERDF, and the Time to Concept chair on the optimization of innovation and training processes in virtual reality, augmented reality and connected objects with Mann Hummel.

This section concerns international applicants who wish to study at Arts et Métiers in the framework of a partnership with a partner university of the school. Please check with your institution first to find out what programmes exist.

Dual degree students attend Arts et Métiers for one or two years in order to graduate from the school at the end of the programme, in addition to their degree at their home institution.

Depending on the inter-institutional agreements between Arts et Métiers and the home institution, the student may apply for one of the following programmes:

The Engineering programme is taught only in French.

Candidates must provide a certificate of level B2. The following certificates are accepted: DELF, DALF, TCF (5 competences) or a TEF (4 competences). No matter the certification, the assessment must evaluate the following skills : writting, speaking, listening, reading.

If candidates cannot provide a French certificate, they can take the Arts et Métiers French test. However this test is not a certification. This means to get their engineering degree students will must to pass the DELF while they study at Arts et Métiers.

Masters courses are taught either in French or in English. Applicants must verify the language of instruction of the Master's programme and provide certification of a minimum B2 level. The following certificates are accepted:

French : DELF, DALF, TCF (5 competences) or a TEF (4 competences). No matter the certification, the assessment must evaluate the following skills : writting, speaking, listening, reading.

English : IELTS, TOEFL, TOEIC (for any other certfification please contact us at admissions@ensam.eu)

Exchange students will follow the courses of a semester or a year, benefiting from an equivalence for the diploma of their home institution (recognition of teaching credits).

Depending on the inter-institutional or Erasmus agreements concluded between Arts et Métiers and the home institution, the student may apply to follow one of the following programmes

Important information:

The Engineering programme is taught only in French. Applicants to the engineering programme must provide a certificate of French at least at B1 level. The following certificates are accepted: certificate from the home university, DELF, DALF, TCF (5 competences) or a TEF (4 competences). No matter the certification, the assessment must evaluate the following skills : writting, speaking, listening, reading.

Masters courses are taught either in French or in English. Applicants must verify the language of instruction of the Master's programme and provide certification of a minimum level of B1. The following certificates are accepted:

French : DELF, DALF, TCF (5 competences) or a TEF (4 competences). No matter the certification, the assessment must evaluate the following skills : writting, speaking, listening, reading.

English : IELTS, TOEFL, TOEIC (for any other certfification please contact us at admissions@ensam.eu)

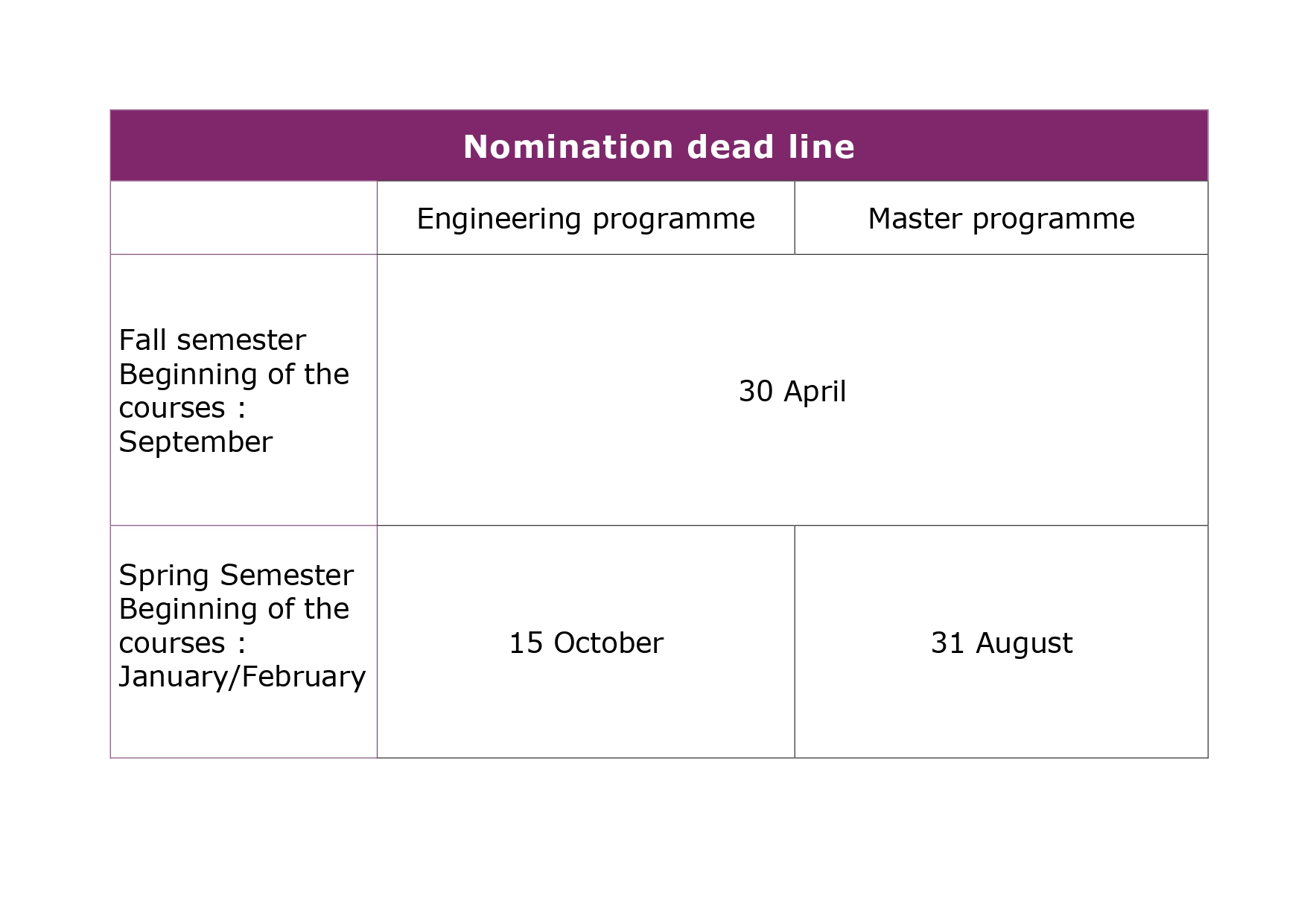

The first step in the admission process is the nomination of pre-selected candidates by their home institution.

The nomination should be sent to admissions@ensam.eu by the home institution.

Once your nomination has been sent by your university and received by our International Relations Department, you will be contacted with the application procedure to follow.

Important: your nomination is only a pre-selection from your home institution. You must apply to Arts et Métiers to carry out your academic exchange. Your admission by Arts et Métiers is not automatic and may be refused by our services.

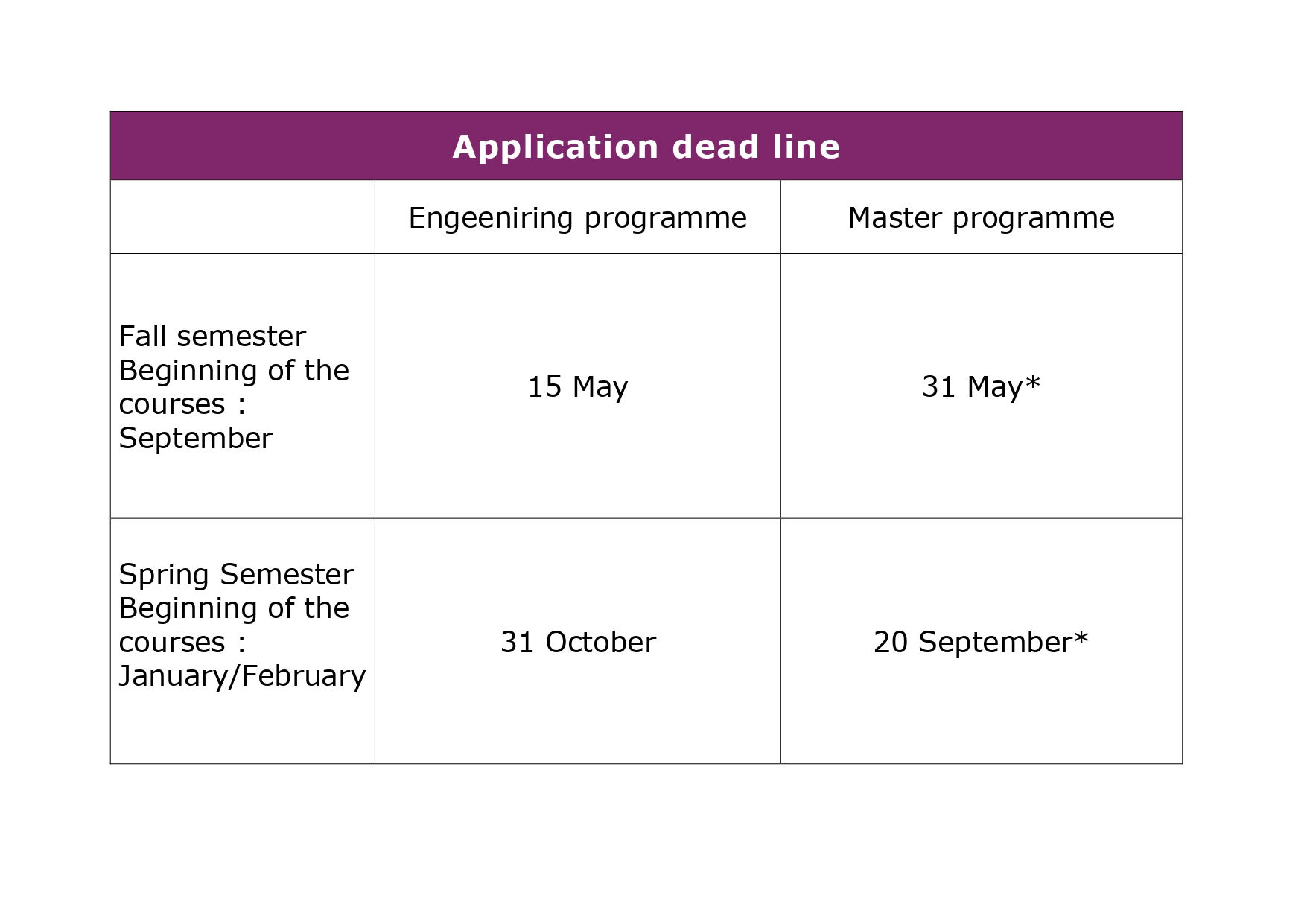

*For National Master Degrees, the application deadline refers to the date of automatic closure of the procedure by the platform. However, applicants must submit their application within two weeks of the start of their online application procedure.

Candidates nominated by their home institution will receive instructions by email on how to apply to Arts et Métiers. Applications can only be made online.

Candidates for the Engineering Programme will have to fill in a form and download the following documents:

Candidates for the Master Degree will have to fill in a form and download the following documents:

Important:

Students are strongly advised to apply as soon as possible and not to wait for the application deadline.

There are several deadlines for applicants related to the home country and the study programme, please check them carefully. Make sure that your complete application, including all required documents uploaded, has been done in the Arts et Métiers online system by the appropriate deadline. Your application will only be assessed if all documents are uploaded in the system before the application deadline. Late or incomplete applications will not be considered. Please note that no printed documents are to be sent by post to Arts et Métiers.

When you have completed all the various sections of the application you will be able to submit it. Kindly note that no more changes will be possible after submitting it.

When you choose your study programme carefully check the campus where the courses are given.

While filling in your application for the Engineering programme you might be asked to sort the campuses in priority order. Campuses are assigned to students early June so, with some exceptions, incoming students do not know their campus in advance even if an admission offer has been sent. We make our best to allocate student’s first choice but, in spite of that, we cannot guarantee a spot in one particular campus. Thus, please do not book housing until you receive confirmation of the campus you have been assigned to.

Admission letters or notifications are sent by email to students and, where necessary, partner institutions.

If hard copies are needed, please let us know.

After receiving your confirmation of admission, Arts et Métiers will provide you with all the information and support you need before making the move to France. Practical matters such as residence permit, accommodation, health insurance, enrollment can be attended to as soon as your admission is confirmed.

If you have been admitted to Arts et Métiers but you are facing a visa problem, a delayed arrival or a request for postponement of admission, please contact the Admissions Department and the International Relations Office on your campus as soon as possible (at the email addresses indicated on your admission letter).

At the time of registration, students will be asked to provide the following documents :

This section concerns international applicants who wish to apply for a degree programme at the school outside a university partnership.

The Arts et Métiers engineer is par excellence the engineer who designs and produces products and production systems. Throughout the three years, the student-engineer builds his training project according to his professional objectives. After the first two years of study, focused on experimentation and mastery of technologies, the student can specialise through one of the 32 « expertises » offered. Graduates work in sectors as varied as the automotive, transport, equipment, chemical, energy, construction, IT, telecommunications and service industries.

To apply for the Engineering Programme, international applicants must have a Bachelor's degree or an engineering degree (or equivalent).

The different admission routes to enter the Grande Ecole programme as a free-mover are listed below. Each of them has a specific calendar, for further information about theses calendar, please visit their website :

ParisTech and N+I are the recommended procedures if the applicant lives abroad. Only international applicants can apply through them. However, it is not possible to submit an application on both platforms; applicants must choose one or the other.

Level of french : B2 minimum

Approved certifications: DELF, DALF, TCF (5 competences) or a TEF (4 competences). No matter the certification, the assessment must evaluate the following skills : writting, speaking, listening, reading.

Arts et Métiers offers Master's degrees in 4 different fields: mechanical engineering, industrial engineering, energy and health engineering. This is a 5-year national degree, which allows students to pursue with doctoral studies and research.

Although a Master's degree takes two years to complete, it is possible to enter the first year and obtain the degree in two years, or to enter the second year and obtain the degree in one year.

The "Health Engineering" specialisation offers several specialisations all taught in English. For more information on the course, see :

The first year of the Master's degree in Health Engineering is accessible to candidates who have validated, or who will validate during the year of application, the equivalent of a bachelor's degree in the field of medical sciences or engineering. This first year, once validated, allows access to the second year of the Master's degree in the same field.

The second year of the Master's degree in Health Engineering is accessible to candidates who have validated, or who will validate during the year of application:

Applications for the 1st and 2d year can only be made via the Master Biomedical Engineering website. They start from beginning of January until the end of May.

Factory of the Future is the name of a first year Master degree at the Arts et Métiers which gives access to the three areas of study : Mechanical Engineering, Industrial Engineering, Energy. This year of teaching is composed of a common core fully taught in english. Its validation allows access to the second year of the Master's programme in the following fields: mechanical engineering, industrial engineering, energy.

The Factory of the Future is open to candidates who have completed or will complete the equivalent of a Bachelor's degree in the fields of science and technology, science for engineers, mechanics.

Applications start from beginning of Frebruary until the end of May via our own application plateforme (see below).

However, once the application is created, the application must be submitted within 15 days.

The 1st year of the Master in 3D Interactive Technologies Management taught in French is part of the Industrial Engineering field. Its validation allow access to the differents specializations of this study area.

The first year of the Master in Interactive Technologies Management is accessible to candidates who have validated or will validate during the year of application, the equivalent of a Bachelor's degree in the fields of science and technology, science for engineers, computer science, computer graphics and media.

Further information about this master are available on the dedicated page.

Application procedures are available on the « Application plateforme » paragraphe below. Applications start from beginning of Frebruary until the end of May.

However, once the application is created, the application must be submitted within 15 days.

During the second year of the Master's programme, students can choose among about twenty specialisation. These specialisations are taught in French and/or English.

Admission to the second year is open to candidates who have validated or will validate, during the year of application, the equivalent of a first year of Master's degree.

Application procedures are available on the « Application plateforme » paragraphe below. Applications start from beginning of Frebruary until the end of May.

However, once the application is created, the application must be submitted within 15 days.

Masters courses are taught either in French or in English. Candidates will be required to provide a B2 level certification in the language of instruction. Here is the list of accepted certifications:

French : DELF, DALF, TCF (5 competences) or a TEF (4 competences). No matter the certification, the assessment must evaluate the following skills : writting, speaking, listening, reading.

English : IELTS, TOEFL, TOEIC (for any other certfification please contact us at admissions@ensam.eu)

Application are opened from Feruary to 31st of May. However, once the application is created, the application must be submitted within 15 days.

1 - Create you online account

2 - Apply

The programme is taught in French and it is not offered to exchange students.

Entry requirements and the specific application process for free-moving students are available here, in French.

The programme is taught in French and it is not offered to exchange students.

Entry requirements and the specific application process for free-moving students are available here, in French.

Programmes can be taught in French or in English.

They are not offered to exchange students.

Entry requirements and the specific application process for free-moving students are available here, in French.

Entry requirements and application process are available here, in French.

Arts et Métiers was in charge of determining piezo locations and of the high-level software interface with CTEC hardware ensuring damage monitoring. We participated in the implementation at TU Delft of the trial campaign.

This FAQ is addressed in particular to international students applying for a national master's degree and to students nominated in the framework of an academic exchange (Erasmus, double degree, non-degree academic exchange).

No. Arts et Métiers does not apply differentiated tuition fees for students enrolled in a master's programme for 2021-2022. For one-year Master’s programme the amount is the same for EU/EEA and non-EU/EEA citizens. More information on our website.

No. Applications or supporting documents received by email will not be considered. You must absolutely go through our online application platform to apply for one of our master's programmes. If you encounter technical issues, please contact admissions@ensam.eu

You will find all the relevant information on our website under the heading “Master’s programme 2 years (Graduate)” and “Master’s programme 1 year (Graduate)”.

You may have difficulties viewing our master application platform for a number of reasons:

- You are using an outdated browser. Use Chrome or Firefox instead.

- Empty your browser's cache and reconnect to the platform.

- Apply via a computer instead of a phone or tablet.

- You are trying to apply for a programme that is not open.

No, you cannot. We receive so many applications that we cannot check them individually before the current batch ends. It is your responsibility.

If you have any doubts about the type of documents required, please contact admissions@ensam.eu BEFORE submitting your application.

We accept almost every certification in English language as long as you obtained the equivalent of a B2 or C1 level (depending on the intended degree). The most common tests are: TOEIC, TOEFL, Cambridge, IELTS.

If you have been graduated in an English-taught programme, you may also provide a certificate to that effect.

There are no minimum grade, GPA or ranking requirements. Your application must be competitive enough to be selected.

The CV and letter of personal statement/motivation MUST be in English and/or in French, depending on the intended degree. If your documents are in a different language, you must have them translated into either English or French in order for your application to be examined.

The letters of recommendation can be written by former or current teachers as well as by people you work with (in case you have already graduated).

There are several ways of applying, depending on your situation:

- via the school entrance exam, after the equivalent of two years of preparatory classes;

- via the entrance exam reserved for holders of a Bac +2;

- via the entrance exam reserved for holders of a bachelor's or master's degree;

- via the N+i programme (admission based on application file).

The double degree programme is only open to students who have been pre-selected and nominated by our partner universities. The engineering programme is taught entirely in French.

The Art et Métiers Master's degree does not confer the title of Arts et Métiers engineer.

The objective of the exchange program is to offer international students the possibility to take classes at Arts et Métiers and receive course approval and credit for their programs at their home institution.

You must apply within the framework of a partnership signed between your university and Arts et Métiers. You must also be pre-selected by your university to apply as an academic exchange student.

Please note that your selection by Arts et Métiers is not guaranteed.

In order to become a double degree student, you must be enrolled at a partner university with which Arts et Métiers has a double degree agreement for the Engineering programme of for a Master’s programme.

You have to study at Arts et Métiers for a period no shorter than 1 years to obtain a master's degree and no shorter than 2 years to obtain the Engineering degree.

For further information about the study scheme and plan, please contact the International office or your academic supervisor at your home university.

Please note that your selection by Arts et Métiers is not guaranteed.

The nomination and application deadlines are indicated on our website.

If you are in a specific situation, please contact us as soon as possible without waiting for the closing date for applications.

No, it is not possible.

If you are coming as part of a double degree, you must present one of the following certificates at registration:

As an exception for candidates who are unable to take the required tests (e.g. due to the closure of examination centres because of a pandemic), Arts et Métiers may provide a non-certifying internal language test.

In this case, during their study period in France, students must pass a DELF B2 test and give the score results to Arts et Métiers, before graduation.

This obligation does not apply to students from French-speaking countries (e.g. Morocco and Tunisia).

Each training programme has specific start dates, courses and exams. These will be communicated to you on your admission letter and by the international relations office of your campus, once your application has been accepted.

No. The school cannot provide you with this type of document. The international relations office on each campus is available to help you find accommodation in France. We cannot ensure that you will get a room in a student residence.

You will receive a link to complete your registration directly online.

Health insurance is mandatory during your studies at Arts et Métiers. As soon as you receive your certificate of enrollment from the Registration Office in your Arts et Métiers campus, you can take out a health insurance policy with the Caisse primaire d’assurance maladie.

EU/EEA citizens holders of a valid European Health Insurance Card (EHIC) are exempt from taking out this health insurance. A copy of their EHIC, valid for at least the 1st year of study at Arts et Métiers, must be provided the registration day.

Important: the French Social Security and the EHIC only entitle you to 60-70% reimbursement of medical expenses, on average, under the French Social Security scheme.

So, it is highly recommended to take out additional insurance coverage, called “complémentaire santé”. This additional coverage is not compulsory but it will make up for all or part of the expenses not covered by the French Social Security. You can sign up with a "mutuelle" or an insurance company.